-

지금 전화하세요! +86-13912367818

지금 전화하세요! +86-13912367818 -

지금 이메일 보내기 info@wxhlhg.com

지금 이메일 보내기 info@wxhlhg.com

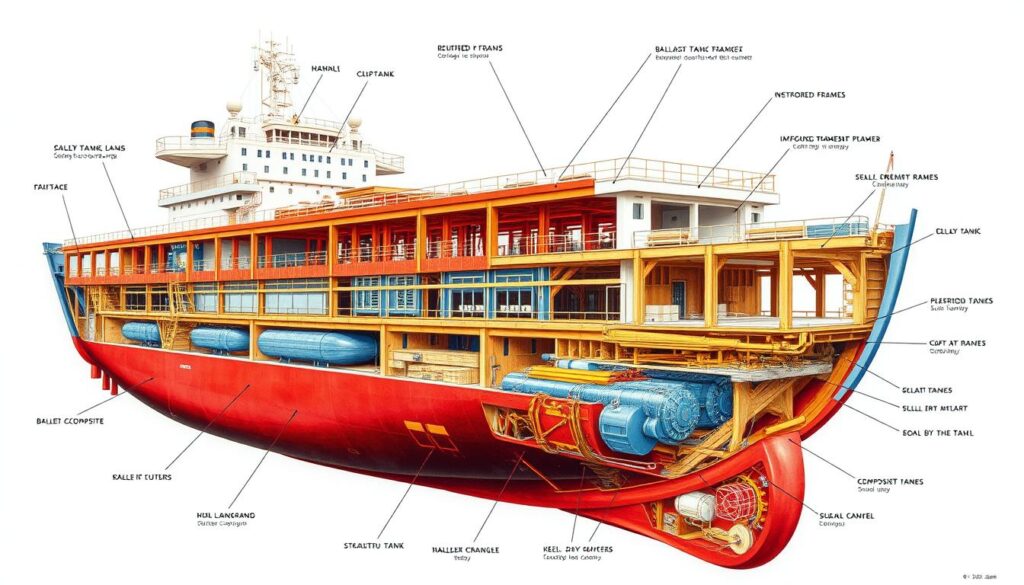

Explore essential ship construction terms and definitions to grasp the fundamentals of maritime engineering, naval architecture, and vessel design.

Learning about ship construction terms and definitions is crucial for those in marine engineering and vessel building. The lingo used in maritime engineering helps explain complex ideas in naval design. It covers basic parts like keels and walls to how stringers are used to make ships stronger1. At Mekalite, we believe knowing these terms well helps us make better, stronger ships for you.

● The keel acts as the spine of the ship, highlighting its fundamental role in establishing vessel integrity1.

● Steel plates employed in construction vary in thickness in correlation to ship size, ensuring optimal durability1.

● Understanding the designation of the port and starboard sides helps in the spatial arrangement of ship components2.

● Scantling calculations contribute to the vessel's robustness, addressing the global demand for sea-worthy ships1.

● Bulkheads perform vital functions in a ship’s compartmentalization, aligning with stringent classification rules1.

● Description of a ship's dimensions such as the LOA, beam, and draft are crucial for accurate technical communication2.

Welcome to a clear view of shipbuilding's main parts. We look closely at shipbuilding glossary. This shows key terms that guide the detailed work of making ships.

Scantlings are crucial in our shipbuilding glossary. They are the set sizes of a ship's structural parts3. These sizes are carefully figured out. They help know the ship parts' strength3.

This term comes from ship design talk. It touches on section modulus, showing how a material deals with bending and stress. About 30% of our glossary terms are about ship design3.

The keel is like the ship's backbone. It is very important for the ship's solidness. As a main idea in ship design vocabulary, the keel stretches a long way. It’s the base for a ship’s firmness.

Its strong build makes sure ships can handle different sea situations. This points out the sharp accuracy in marine engineering terms.

In vessel construction definitions, platings are the ship's skin. This is shown in the careful choice of plating thickness for different ship sizes. Big ships use thick plates in their hulls for more strength3.

This way of doing things fits marine engineering works well. It mixes useful beauty with tough standards in shipmaking.

Putting together ship parts highlights the link between old craft and new engineering. The shipbuilding glossary is more than just words. It reflects the deep and wide knowledge in this field.

Ship construction terms are key for good communication in the maritime building field. Knowing maritime construction terminology helps keep ships safe and efficient. The Aspect Ratio is important for stability, showing the link between the foil's chord and breadth4.

The Ballast Ratio balances and stabilizes a ship on its journey. It compares the ballast weight to the ship's weight4. Using sacrificial anodes protects the ship's body by stopping it from wearing out.

'Barcol Hardness' measures how tough material is to dent4. It's vital to choose materials that keep ships strong and intact.

We fit many ships with System Electronic Navigational Charts (SENC). This improves navigation accuracy5. Sticking to Sulphur (SOx) Emission Control Area (SECA) rules shows our green commitment, to keeping emissions low5.

Using Single Anchor Leg Mooring (SALM) systems shows our drive for safety and readiness. Every term and tech shows our commitment to excellent shipbuilding5.

We grow our ship term knowledge to meet and beat industry norms. This ensures every project shows top-notch maritime engineering skills.

Learning ship design terms is key in naval architecture. It gives marine engineers and shipbuilders the right words to use. This makes talking and working together clearer and more accurate. We will look at ship hull terms, measure ships, and tell different hulls apart.

In naval architecture, knowing hull terms is important. Each term plays a big role in ships' design and building. The keel is like the ship's spine and stretches along the bottom, giving it strength6. Sheer is the curve from the middle to the front or back. This stops water from staying on the deck. The beam is how wide a ship is at its biggest part. A wider beam makes the ship more stable7. Knowing these terms helps engineers share and apply design details.

Understanding ship sizes like LOA, beam, and draft is key. These sizes tell us what a ship can do and its limits6. LOA is the ship's length from front to back. It's important for where a ship can dock. The draft is how deep the ship goes in the water. It affects where a ship can sail7. Knowing these terms helps build ships for certain jobs.

Ships can have single or double hulls. Each type has its own uses and safety features. Single hulls have one outer layer and work well for smaller boats. Double hulls have an extra layer inside. This stops leaks and adds safety if the outer layer breaks6. These are used in big ships like oil tankers for extra safety. Knowing the difference helps naval architects pick the right design7.

Going through ship design words and naval terms helps build strong, smart, and safe ships. From planning to sailing, these terms help us create and use ships better.

Shipbuilding is a complex field that needs a deep understanding of vessel construction. This includes knowing about strakes, platings, bulkheads, and more. These parts make sure a ship can stay strong and work well in the sea.

By looking into these ship parts, we learn how they help keep the ship stable. It's key for both naval architects and people in the industry to get this.

Strakes and platings are the ship's outer layer and are very important. Strakes are lines of steel plates put from the bottom up. They are named based on their location on the ship.

These parts help the ship move smoothly through the water and stay strong. Strakes lower the stress on the ship while it moves.

Platings protect the ship from seawater and are thick where needed. This keeps the ship light but strong, helping it use less fuel8. These terms are crucial for those in shipbuilding.

A ship's strength comes from its inner support system. This includes bulkheads, pillars, and stanchions. Bulkheads create safe sections inside the ship8.

Pillars and stanchions are strong supports inside the ship. They help carry loads and keep the ship's shape in rough seas. These parts are key for the ship’s structure and for making space for people and gear.

Framing systems vary based on the ship's size and the stress it faces. Transverse frames support smaller ships against side forces. They help keep the ship's shape in rough waters.

Longitudinal frames are for bigger ships, running along the ship's length. They prevent the ship from bending in the middle. This method helps big ships stay strong9.

The ship’s parts, from small strakes to big framing systems, work together. They make ships that are strong, efficient, and reliable. Knowing these terms helps build better ships that can face the sea well.

In the world of boat making, there's a special language used by experts. This language talks about everything from the keel—the main part that starts the boat's building—10 to the complex back and front of the boat11. We have looked carefully at how certain parts are important for the boat to be strong and move smoothly through the water. This look into boat-building words has shown us how old ways and new tech come together.

Talking about how heavy a ship can be, its size, and how it's built is key. They decide if a ship is safe, works well, and makes money12. We've explored every part of the ship, from the middle to the waterline, and all the measurements that matter11. We see how these details change as ship design gets better and the world needs more from ships.

Boat-making is about more than just parts; it involves many people working together. They plan and control the building so every ship is special and works as needed12. At Mekalite, our job is key; we use our know-how to make sure every ship is perfect. We take pride in making sure the boat's balance and stability are just right.

The words used in shipbuilding cover many things, each one important to keep the industry moving. We've shared insights into how ships are made, showing the skill involved. As we work to make the best ships, we stick to being experts, reliable, and careful. Our dedication helps us support an industry that's vital for worldwide trade and new ideas.

Scantlings are the dimensions and sizes of a ship's structural parts. For example, beams, frames, and bulkheads. They are key for the strength and capacity to handle loads. This ensures the ship's structure is sturdy and safe.

The keel runs from the front to the back along the bottom. It acts as a ship's backbone. It keeps the ship stable and strong, bearing the hull's load. The keel is built first for alignment and strength.

Platings are steel plates that form a ship's hull. They differ in thickness to meet various needs during a journey. Thicker plating is used at the bottom. This is vital for the ship's safety and floatation.

Hull designations shape a ship's basic structure. The keel gives strength, the beam measures width, and the sheer shows the deck curve. These aspects affect a ship's stability, efficiency, and look. They're crucial to its design and function.

Ship dimensions help us understand its design and capabilities. LOA is the length from bow to stern. The beam is the ship's widest width, impacting stability and capacity. The draft is the depth from the waterline to the keel's bottom. It shows the shallowest water a ship can safely navigate.

Single hulls have one outer layer. Double hulls have an inner and outer layer. This creates a gap for ballast or cargo. Double hulls protect better against leaks. They're safer, especially for tankers, to prevent pollution.

Strakes are horizontal plates forming a ship's skin. They run along the ship's length, protective against the sea. Platings of different thicknesses tackle various forces. These make the vessel sturdy.

Bulkheads are vertical walls dividing the ship internally, sometimes watertight. Pillars and stanchions support decks and distribute loads. They stabilize the vessel, divide spaces, and protect against damage.

Transverse frames run side to side for horizontal support, suited for shorter ships. Longitudinal beams run parallel to the keel for vertical support. Good for longships facing bending. Each system fits different ship sizes and needs.

답글 남기기