-

Appelez maintenant ! +86-13912367818

Appelez maintenant ! +86-13912367818 -

Envoyer par courriel info@wxhlhg.com

Envoyer par courriel info@wxhlhg.com

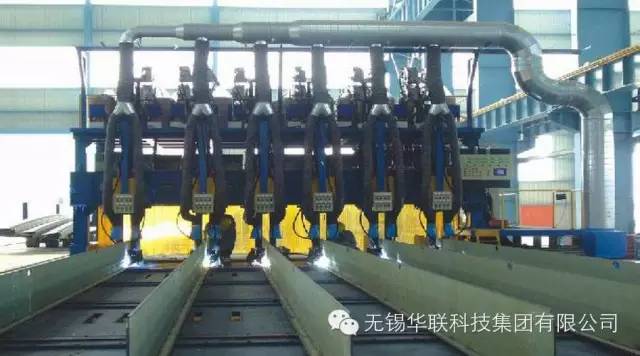

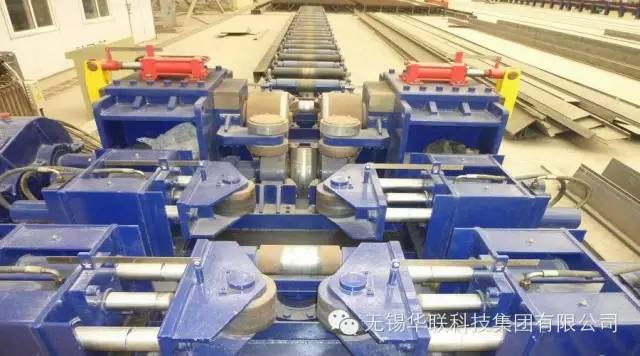

The T Beam Welding Machine is a compact, all-in-one solution for assembling, welding, and straightening T-beams. Its space-saving design and multifunctional capabilities allow for seamless and simultaneous processing, improving efficiency and precision.

This assembly line is a special production line for high-efficiency mass production of marine T-shaped rows. The assembly line is equipped with panel positioning device, web positioning device, T-shaped row assembly, positioning welding device, T-shaped bar diverter device, and panel four-corner chamfering. Machine, T-shaped row transverse discharging device, T-shaped door welding machine, T-shaped straightening machine, conveyor roller and other auxiliary equipment realize the automation of the T-shaped row assembly process. The whole process is automatically controlled by PLC, and each process is equipped with safety alarms and interlocks to ensure safe and sequential production in every link.

T-profile assembly and welding production line equipment list

1. Web positioning device A

2. Web positioning device B

3. Panel positioning device

4. Positioning welding input roller

5. T-profile assembly device

6. Electronic control system and pneumatic control system

7. Positioning spot welding device

8. Positioning welding output roller

9. T-shaped diverter device

10. Input roller table of chamfering machine

11. Chamfering machine host

12. Output roller table of chamfering machine

13. Support platform

14. Support platform

15. Welding platform clamping device

16. Welding platform turning device

17. 24-electrode door type automatic welding machine

18. HL06-00T profile hydraulic straightening machine

Note: Specific equipment configuration can be configured according to customer needs.