-

Appelez maintenant ! +86-13912367818

Appelez maintenant ! +86-13912367818 -

Envoyer par courriel info@wxhlhg.com

Envoyer par courriel info@wxhlhg.com

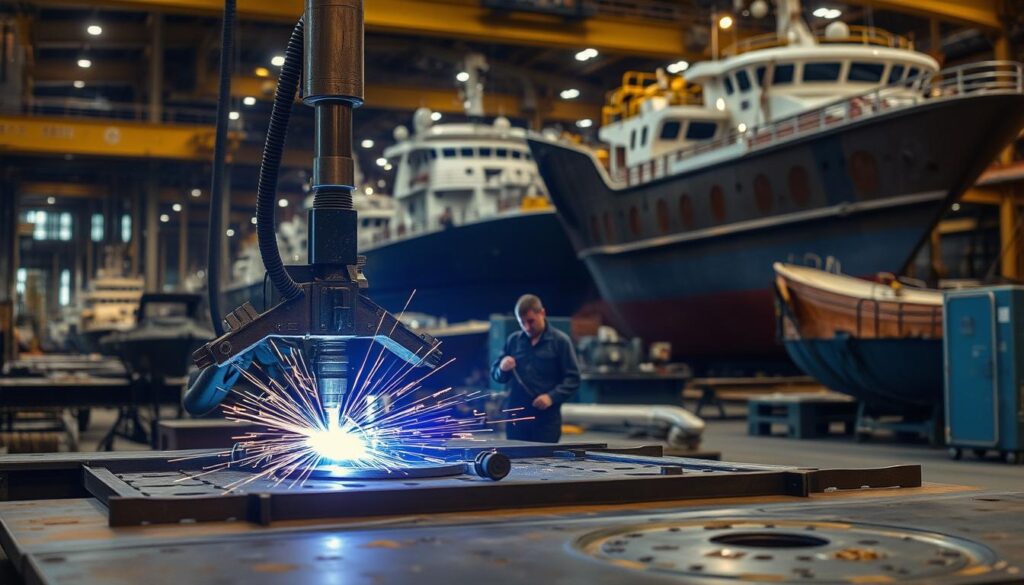

Explore how plasma cutting technology revolutionizes shipbuilding cutting and grinding for better precision and efficiency in marine construction.

In shipbuilding, being precise is crucial. Plasma cutting technology is a big leap forward. It sets new standards for cutting and grinding ships. This technology can quickly cut materials up to 50 mm thick. It makes shipbuilding faster and more precise. Every cut helps make the ship stronger. Plasma cutting also reduces costs and works well with computers for automatic cutting. It keeps quality high, even when making lots of cuts123.

● Plasma cutting boosts throughput, cutting up to 2 times faster than alternatives for thinner materials1.

● Superior precision is achieved with plasma, necessary for the complexity of ship components3.

● Advancement in CNC technology facilitates a streamlined production, from design to assembly1.

● Cost savings are realized through lower operating costs compared to more traditional methods1.

● Incorporating safety measures, such as proper eyewear and ventilation systems, remains a top priority during cutting operations.

● Cobots are emerging as a solution to handle hazardous aspects of plasma cutting, improving safety and productivity.

A new era in shipbuilding is here thanks to CNC plasma cutting. This technology changes old methods into efficient, precise ones. It boosts efficiency and brings high-quality and eco-friendly shipbuilding.

CNC machining helps shipyards like Geoje. They use robots in about 68% of their work, reducing risks and mistakes. CNC lets builders make complex cuts with accuracy and speed. Big names like Mitsubishi and Wartsila use high-efficiency engines and automated systems to meet today's needs.

Plasma cutting heats up to 20,000°C, cutting materials quickly with little waste. It's faster and more precise than older methods. Using gear like Hypertherm Powermax® and Lincoln Electric ProCut™ means cuts are always good

CNC plasma cutting stands out for precise, adaptable work. Robots make fast torch moves for big orders, improving speed and quality. New materials like bucky paper boost fuel efficiency and cut emissions. Ships get faster and greener

CNC machining is key in modern shipbuilding. It's not just an upgrade, but essential for a strong marine industry. It ensures top tech is used in building ships, making each part and vessel a symbol of precision, safety, and tech unity.

In shipbuilding, using resources wisely is very important. Advanced cutting methods like plasma and laser are key. They help use materials well, save resources, and cut costs.

Shipbuilders use nesting software with plasma cutting to place parts smartly on sheets. This setup helps reduce leftover material. It's all about cutting down waste in metalwork and is key to being eco-friendly in shipbuilding. Laser cutting also helps by reducing damage from heat and keeping materials strong, leading to less waste and more efficiency.

Laser cutting is known for its sharp precision. It makes cuts with smooth edges that don't need extra finishing. This method fits well with the goal of using materials wisely and working more efficiently. Lasers can work with many materials, which is great for eco-friendly shipbuilding.

● Maximizes resource efficiency by reducing material wastage through precision cuts

● Enhances production timelines by minimizing the need for additional finishing processes

● Preserves material quality and properties, which is critical in the construction of durable seafaring vessels

To wrap up, precision cutting in shipbuilding is about more than just working faster. It's key to being sustainable. As technology gets better, using these cutting methods stays central to saving materials and reducing waste54..

In the quest for progress within the marine industry, we focus on better material use and new tech. It's all about making shipbuilding better and greener. This is our goal in the modern world of making ships.

Today, making ships sustainably is a must, not just a choice. Using materials wisely reduces waste. This is key because shipping materials are expensive. Small trucks, rather than big cranes, show how we save money and handle heavy ship parts. These can be over 1,000 tons6. Saving on materials is about smart logistics and caring for the planet.

Automated cutting is key in making shipbuilding faster. Techs like precision plasma cutting ensure we cut right and waste less. With smart software, these machines make our work reliable. They keep our ships up to high standards.

Shipyards use monitoring systems to keep an eye on parts. This ensures every step is done right7. Adding green tech to our work meets tough environmental rules7.

By using automated cutting and green methods, we're not just updating; we're investing in the future. These steps make shipbuilding better and kinder to our planet. This ensures we can keep building ships well into the future.

Plasma cutting has changed how we cut and shape materials for shipbuilding. It cuts through tough steel easily, important for safe ships.

Shipyards love plasma cutting because it works with different alloys. It makes the shapes we need in shipbuilding8. It's reliable and versatile, making it key in ship construction.

Laser cutting is also making waves with its cleanliness and efficiency. It's cost-efficient and precise, loved in many places9. Laser-arc hybrid welding makes production much faster and precise10. Laser cleaning gives great control and boosts efficiency in cleaning10.

Mixing old and new cutting methods cuts costs and helps the environment. It makes shipbuilding faster, more accurate, and cheaper8.

| Technology | Application in Shipbuilding | Efficiency Gain |

| Laser Cutting | Cost-efficient cutting across various industries including shipbuilding | High precision at reduced costs |

| Plasma Cutting | Cutting through various alloys in shipbuilding | Reliable handling of diverse metal types and thicknesses |

| Laser-Arc Hybrid Welding | Optimized production efficiency | Up to 10 times faster production |

| Laser Cleaning | Post-cut cleaning with micron-level precision | Enhanced energy efficiency |

Plasma cutting and laser tech are key in modern shipbuilding. They help us build better, safer, and cheaper ships. These tools are shaping shipbuilding's future, toward being more eco-friendly and cost-effective.

In shipbuilding, using advanced tech like plasma cutting is essential. It helps us stay competitive and maintain high quality. We focus on quality assurance in shipbuilding by using strict steps and advanced tools. These improve how precise and reliable our work is.

After plasma cutting, each part is checked closely. This ensures they meet strict quality rules. These checks are key to making sure each piece fits perfectly and works well. Things like how fast we cut, the gas used, and the nozzle shape are carefully watched. This care helps make shipyard-cutting solutions effective. Plasma cutters help us make complicated ship parts easily11.

We use traceability systems in making ships. Every plasma-cut piece gets a special number. This helps us keep track of everything from start to finish. This system makes managing projects and quality control easier. It also helps us keep getting better. Plus, it supports handling big projects without losing track of traceability in marine fabrication.

To sum up, careful quality control and strong traceability systems make our naval designs better. By improving these areas, we keep being leaders in shipbuilding excellence.

| Fonctionnalité | Advantage | Impact on Shipbuilding |

| Advanced plasma cutters | Precision in complex cuts | Increased fabrication efficiency and quality11 |

| Unique part numbers | Efficient traceability and QC | Enhanced project management capabilities |

| Meticulous inspections | Adherence to specifications | Guaranteed structural integrity and performance |

In today's world, using innovative shipbuilding technology is key to doing better in the marine industry. CNC plasma cutting is a big step forward in making work faster and better.

Automation in ship construction, like CNC plasma cutting, is really good because it's fast and accurate. This method makes cutting sheet metal much quicker. This speeds up how much we can make without losing the quality that's very important for ships12. CNC plasma works well with other steps of building a ship. This keeps everything moving smoothly from cutting to welding, and then to painting.

CNC plasma cutting isn't just for cutting. It's made to work well with the next steps in building ships. This improves productivity in the marine industry by making things run smoother and with fewer delays12. This good mix helps make shipbuilding better. Projects finish on time because every part works well together.

● Elevated Efficiency: Automated cutting makes using resources better, lowering waste. This is both good for money and the planet13.

● Enhanced Precision: New cutting ways are very exact. This is important for making complex parts of ships, making them work and last better14.

● Reduced Operational Costs: Using machines more means building faster. This also means paying less for labor and making fewer mistakes, which saves money1314.

New tech in shipbuilding helps make more ships. It also lets the industry meet the growing need for ships better. As we improve these technologies, the future of making ships looks bright.

The skill of the operator in plasma cutting is very important, especially in shipyards. This technique needs both good equipment and skilled people to work well. In shipyards, the full benefits of plasma cutting are seen with skilled work.

Well-trained operators are key to shipbuilding. They handle complex machines and CNC systems. The heat from plasma cutters can melt metals quickly, reaching up to 30,000 degrees Celsius15.

This allows them to cut thick metals like steel and aluminum15. These metals are common in making ships.

Having skilled operators means work is safe and productive. They use CNC systems for precise cuts, speeding up shipmaking. This method is very accurate, with a low error margin16. It meets the high quality required in shipbuilding.

● Plasma cutting is safer than other methods, reducing injury risks from sparks or shrapnel15.

● It is also cheaper, needing less prep work16. This saves money for shipyards.

● The technique is versatile, even working underwater for safer and quieter operations15.

Operator skill in plasma cutting is crucial in shipyards. As shipbuilding technology grows, the need for skilled operators will too. They play a big part in using new technologies for better ship making.

The future of shipbuilding relies on high precision in ship making and new maritime techniques17. Think about how ships, like cargo vessels and cruise ships, are made. The role of advanced plasma cutting plays a big part17. Different cutting methods are important for making and finishing ship parts. It's also critical to keep workers safe with the right gear17.

Using new methods helps make the building process better. Tools like abrasive wheels help make ship parts like hulls and decks17. Keeping these tools in good shape and using trusted methods mean the ships we build are top quality17. Honxin Abrasive's long history of quality shows our commitment to making the best products. This helps ships last longer, thanks to ongoing tech research18.

We are proud to be part of shipbuilding's future. Our focus on improvement and making customers happy strengthens our role in this field18. We are dedicated to making ships that are strong, reliable, and perform well. This shows our promise to be the best in making and shipbuilding.

Plasma cutting is key in shipbuilding for its precision and speed. It cuts and grinds with accuracy, important for big, complex ship parts. This accuracy helps meet high-quality standards, uses materials well, and cuts waste.

CNC plasma cutting has changed shipbuilding from manual to automated. It makes parts straight from digital designs, boosting accuracy and speed. This new approach improves the whole process, making cutting faster and smoother.

CNC technology automates cutting, making shipbuilding faster and more consistent. It works with CAD and Nesting software. This helps better plan and use materials, enhancing digital construction.

Plasma cutting helps make shipbuilding sustainable by smart material use. Nesting software helps cut down on waste. This means using resources better, making shipbuilding more eco-friendly while saving materials.

Yes, plasma cutting is great for cutting thick steel in ships. It's precise and accurate, which is crucial for a ship's safety and structure. And it does this without harming the material's quality.

Plasma cutting offers clean, precise cuts for top-notch ship parts. After cutting, parts are carefully checked. A tracking system ensures each piece meets quality standards, improving shipbuilding.

Expert operators are crucial in plasma cutting. They handle CNC machines with skill, making smart adjustments. Their skill keeps the high quality of ship production steady.

Automated plasma cutting speeds up shipbuilding and keeps quality high. It fits well with other shipbuilding steps, from welding to painting. This makes shipyards more efficient and productive.

Laisser un commentaire