-

Jetzt anrufen! +86-13912367818

Jetzt anrufen! +86-13912367818 -

Jetzt mailen info@wxhlhg.com

Jetzt mailen info@wxhlhg.com

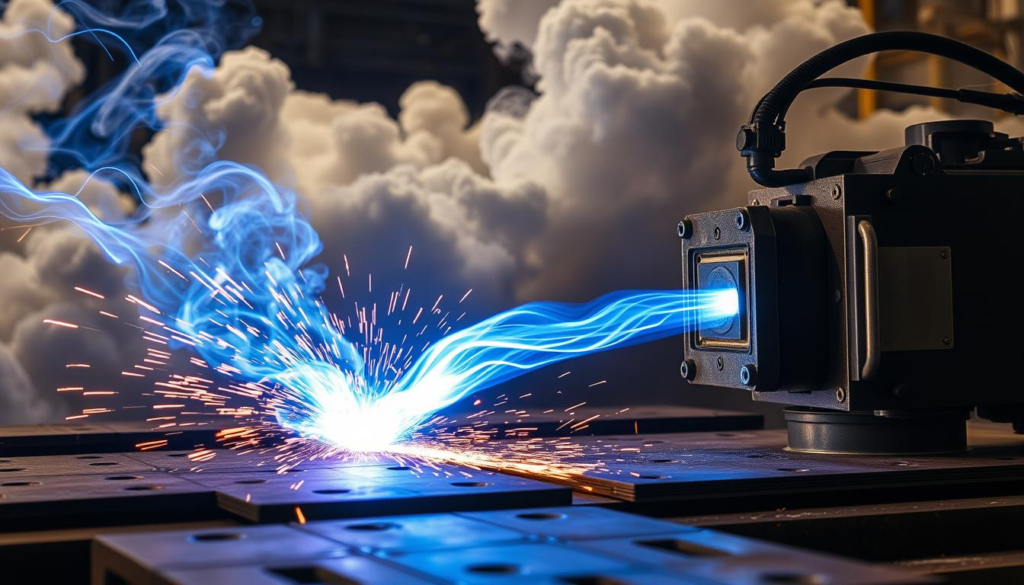

Discover the ideal gas for plasma cutter use and enhance your cutting performance. Learn about the best options for different materials and applications.

In manufacturing and metalwork, choosing the right gas for a plasma cutter is key. This choice impacts how well the plasma cutter works on different metals. These metals include carbon steel, stainless steel, aluminum, and others1. Each gas has its own benefits, depending on the metal and the cut needed.

Common gases used are air, oxygen, nitrogen, and argon, sometimes mixed with hydrogen. Compressed air is great for many metals and low current cutting. Oxygen allows for clean cuts and fast cutting speeds on carbon steel1. Nitrogen is good for cutting thick materials and is cost-effective. Argon keeps the arc stable and prevents contamination1. Hydrogen is used for cutting metals like aluminum and stainless steel because it cools the metal quickly1.

Choosing the right gas involves more than just the type. You must consider gas purity, how well it works with your equipment, and the cost. Nitrogen can become costly for those who use it often due to high-pressure needs. Some methods, like cutting underwater, can improve cut quality without needing pricier gases2.

Understanding how different gases affect the cutting process helps get the best results. Using hydrogen for its cooling properties or mixing nitrogen with water can keep the cut area clean. These tactics achieve cleaner cuts on sensitive metals1.

● Compressed air is versatile and affordable for cutting many types of metal1.

● Oxygen helps achieve clean, fast cuts on carbon steel up to 1 ¼" thick1.

● Consider costs and needs when using nitrogen for thick materials2.

● Argon and hydrogen are best for special cutting needs that require cool, high-quality cuts1.

● Cost and material type are important in choosing the right gas for the best cut quality and speed12.

In today's manufacturing, picking the right plasma cutting gas is crucial. It greatly affects how well things run and the quality of the cut. Knowing the plasma cutting method and the different plasma cutter gas types is key for top efficiency and performance in cutting tasks.

Plasma cutting uses an ionized gas jet to heat and melt stuff neatly. It can reach super hot temperatures of up to 30,000 degrees Celsius3. This is enough to cut through materials over 5 inches thick3. As it melts, the material, a fast gas stream, blows away the melted metal, making a neat cut.

This cutting way is really versatile, working well with various gases for different jobs. The choice between single or dual-gas systems can affect the plasma cutter's performance. For instance, using dual or multi-gas systems4 allows better control over cut quality, making them a top pick for many workers due to their flexibility and excellent results.

The gas in plasma cutting makes the plasma and safeguards the cut from air contamination, keeping the cut's quality intact. Different gases work best for various materials:

● Mild steel cuts faster and cleaner with oxygen4.

● Nitrogen gives a neat cut for aluminum and stainless steel and makes parts last longer.

● For thick stainless steel and aluminum, argon-hydrogen mixes up the cutting power for up to 6-inch materials4.

● And for saving money, clean, dry air works well for lots of materials like aluminum and mild steel4.

Choosing the right plasma cutter gas types boosts performance, saves on costs, and lessens maintenance needs. Understanding each gas's unique traits, from air to special mixes like argon-hydrogen, is key for excellent cutting results.

To wrap it up, knowing and picking the right plasma cutting gas and gas supply for plasma cutting is super important. By matching the gas to specific materials and cutting needs, makers can improve their plasma cutting systems' efficiency and lifespan.

Choosing the right gas is key in plasma cutting. Compressed air is the top pick because of its versatility. It's crucial for making precise cuts.

Compressed air is not just easy to use; it's great for many materials. It makes clean cuts on mild steel, stainless steel, and aluminum. Plus, it's the cheapest option, cutting down on gas costs56.

In the manufacturing world, everyone knows that compressed air is affordable. It's because air is everywhere and doesn't need expensive tanks or big storage7.

Using compressed air for plasma cutting is useful, but it has its challenges. The main issue is stopping oxidation on the cut surfaces. This is important to make sure welding later on goes well.

It's also important to think about how thick the metal is and what kind it is. Compressed air works best for metals up to one inch thick. This way, the cut's quality stays high5.

To sum up, compressed air is often the best choice for plasma cutting. But, it's important to look at both the good and the bad sides to use it right. Doing this shows our dedication to precision and quality in plasma cutting.

Oxygen is a top choice for cutting carbon steel with a plasma cutter. It's known for its efficiency and effectiveness. Our aim is to give you tips to make your manufacturing better.

Oxygen speeds up cutting on mild steel. This is great for saving time without losing quality. It makes the edge a bit rougher, but that's often okay. This means you can get more done without harming the cut's quality8.

Hypertherm's plasma cutters use oxygen to keep edges from getting too hard. This makes it easier to do other work on the steel later. Oxygen is really the best for cutting carbon steel9.

Oxygen works best with carbon steel only. Using it with other materials might not give the best results8. It can also make things more expensive because you'll need to replace parts more often8.

Even though oxygen helps cut faster and better, it costs more. You'll use more gas and need new parts sooner10.

At Mekalite, we want to help you find the best plasma cutter gas. Choosing the right gas, like oxygen for carbon steel, makes a big difference. It saves money and improves your cuts.

In the quest for efficiency and quality, choosing the right gas for plasma cutting is key. Nitrogen is a great choice for many cutting needs. It's affordable and works well for different materials.

When you use nitrogen with a plasma cutter, the cuts get better. This is especially true for thick materials like stainless steel and aluminum. Cuts are clean and precise, making nitrogen perfect for important projects. It also keeps the material in good shape by reducing heat damage

Mixing nitrogen with water improves cuts on materials like aluminum. This combo produces clean cuts and is better for the environment

Adding nitrogen to argon helps with welding, keeping costs low but quality high. For thin stainless steel, a mix called F5 makes the cuts look better and of higher quality

Knowing how to pick the right gas for plasma cutting shows why nitrogen cutters are popular. They support many jobs without costing too much or sacrificing quality.

Argon plasma cutters bring a big change in metal work. They provide clean and consistent cuts. This is very important for success in the industry. Using argon for plasma cutting makes use of its non-reactive nature. This is key for making precise cuts without any contamination.

Argon is very important for plasma cutters because it helps keep the plasma stable at high temperatures. This results in top-quality cuts11. Engineers mix argon with other gases to cut materials like stainless steel1211 better. This makes plasma cutters more versatile and able to work with many metals.

Mixing argon with hydrogen helps a lot with cutting thick materials. This combo allows for quicker cutting and keeps the quality high13. It's especially useful for tough projects that need both speed and precision.

Here, we show a table that compares argon to other gases in plasma cutting:

| Gas Type | Cut Quality | Speed | Materials Suitable |

| Argon-Hydrogen | Hoch | Fast | Stainless Steel, Aluminum |

| Oxygen | Medium | Very Fast | Carbon Steel |

| Nitrogen | Medium | Medium | Mild Steel, Stainless Steel |

| Air | Lower | Slower | Mild Steel, Aluminum |

Choosing the best gas for your plasma cutter, like an argon mixture, is smart. It makes sure your cutting work is well done and efficient. Argon makes plasma cutting more flexible and effective, giving clean cuts and less waste121311.

Selecting the right gas for plasma cutting is key to getting good results with different materials. Hydrogen helps a lot in improving the quality and speed of cuts. It works even better when mixed with other gases. This shows how adding hydrogen to gas mixes makes a hydrogen plasma cutter do better.

Hydrogen makes the plasma hotter. This is key for cutting thick and hard materials. It leads to cleaner cuts and less slag. For example, a mix of 35% hydrogen and 65% argon cuts thick stainless steel well14. Hydrogen is also great for high-quality and slag-free finishes. A mix called F5, which has 5% hydrogen and 95% nitrogen, is great for cutting thinner stuff up to half an inch14.

| Material | Gas Mixture | Optimal Thickness |

| Stainless Steel | H35 (35% Hydrogen, 65% Argon) | Up to 0.75 in |

| Mild Steel | F5 (5% Hydrogen, 95% Nitrogen) | Up to 0.5 in |

| Aluminum | Specialized mixes with hydrogen | Up to 160mm |

But using hydrogen has its downsides. The high heat can wear out cutting gear faster. So, you need to carefully control things like gas pressure and torch settings1415. Luckily, advances in the field are helping make hydrogen a practical choice for lots of cutting jobs15.

In sum, knowing and using hydrogen in plasma cutting gases boosts cutting performance. It also makes hydrogen plasma cutters more flexible to meet new needs in metal making. Using hydrogen in gas mixes is vital for precise and high-quality cuts.

Choosing the right gas is not just about saving money. It greatly affects the cut's quality and the cutting speed. Making a smart choice can boost your work efficiency and profit.

Compressed air is often used because it is affordable and works well for simple jobs16. Nitrogen is great for cutting materials like aluminum and stainless steel. It makes cuts cleaner and parts last longer16. For metals that need a perfect finish, mixing argon with hydrogen is key. It cuts cleanly, reducing extra bits and bending16.

Using oxygen speeds up cutting steel but means you'll change parts more often16. For thick materials, argon and hydrogen or nitrogen with water work best. They ensure precise cuts and are efficient16.

Different materials react differently to various gases. For example, nitrogen is perfect for a clean cut on stainless steel but not on all materials17. Keeping an eye on cutting settings like voltage and gas flow is important. It helps keep cuts good across different materials17.

Good grounding is very important. A bad plasma arc can ruin the cut quality. You must also adjust the cutting speed based on the material thickness. Cut slower for thick metals and faster for thin ones17.

| Gas Combination | Mild Steel | Stainless Steel | Aluminum |

| Oxygen | Fast, rough edge | Not recommended | Not suitable |

| Air | Adequate, cost-effective | Less precise cut | Less precise, sustainable |

| Nitrogen | Slower, cleaner cut | Clean, precise cut | Clean, extends parts life |

| Argon-Hydrogen | Superior quality, slower | Enhanced precision, reduced distortion | Superior finish, less slag |

Looking into different gases for plasma cutting showed us a lot. Picking the right gas is crucial. It really affects how well and how cost-effectively the cutting is. Compressed air is common and good for many uses, especially for cutting materials up to 1 inch thick1819. If you need more precision and quality, nitrogen is great for materials up to 3 inches thick1819. Oxygen makes very good cuts on carbon steel up to 1/4 inch thick18.

For materials like stainless steel and aluminum, mixing gases can be very helpful. A mix called H-35, with argon and hydrogen, can cut through more than 5 cm thick18. F5 mixtures, with more nitrogen, work best for stainless steel18. When choosing the best gas, think about what metal you're cutting. Also, consider gas availability and cost19.

People making decisions in manufacturing need to know about plasma cutter gases. The tech has gotten better since the mid-20th century20. The right gas choice ensures fast production and great quality. This matches our goal of providing top advice and results1820. Using the best plasma gas improves your work and delights customers. We believe this knowledge will make your business practices better, taking plasma cutting to the top.

Plasma cutting uses gases like compressed air, oxygen, nitrogen, and argon. Sometimes, hydrogen mixes with these gases. This mix boosts their cutting power.

For various materials, compressed air is a good choice. Oxygen is well for cutting carbon steel. Nitrogen is great for stainless steel and aluminum. Argon-hydrogen is best for thick and precise cuts.

Choosing the right gas affects how fast and well you can cut. It also keeps your equipment lasting longer. Each gas has a unique way of working with different materials. This makes cutting efficient.

Yes, compressed air works on many metals, like mild steel, stainless steel, and aluminum. But, it might cause oxidation. This could impact welding quality.

Oxygen makes cuts in mild steel fast and clean. You'll see less dross. But it might wear out your tools faster because of oxidation.

Nitrogen ensures high-quality cuts on bright metals. It's great with other gases for thick materials. Nitrogen reduces oxidation risk. This makes it a top pick for stainless steel and aluminum.

Argon, mixed with hydrogen, helps cut thick materials and special metals. This combo gives precise cuts without contamination. It's good for stainless steel and aluminum.

Hydrogen is mixed for its cooling and thermal conductivity. This helps a lot when cutting metals like aluminum and stainless steel. It enhances the cutting process.

The right gas choice boosts cut quality and speed. For instance, oxygen and nitrogen help make clean cuts. A mix like argon-hydrogen is better for thick materials, offering top results.

Yes, you must consider the material type and thickness. The desired cut quality and plans for welding matter, too. The metal's reaction to the gas affects the final cut's look and strength.

Schreibe einen Kommentar