-

Jetzt anrufen! +86-13912367818

Jetzt anrufen! +86-13912367818 -

Jetzt mailen info@wxhlhg.com

Jetzt mailen info@wxhlhg.com

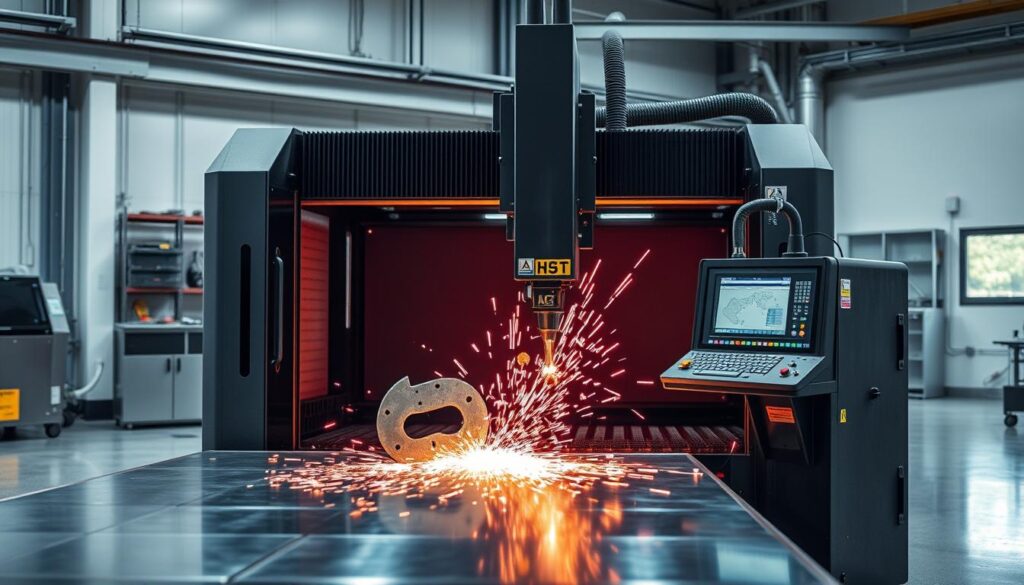

Discover unparalleled precision plasma cutting with advanced CNC technology for high-quality metal fabrication and custom cutting solutions.

Precision plasma cutting is a key part of metalwork. It combines CNC tech with high-speed plasma for top-quality work. This mix gives us neat cuts that help with both art designs and tough industrial parts. We use the latest in plasma cutting to show our focus on quality. With speeds up to 100 inches per minute on 0.25-in. steel1, our high-precision systems can handle big challenges.

Our setup includes plasma power, CNC, torch height control, and gas control console1. This lets us work fast and save costs. Our process is also quicker than many other metal-cutting methods.

● Advanced CNC technology enables top cutting speeds and intricate precision in metal fabrication.

● Extended consumables life ensures fewer interruptions and higher efficiency in plasma cutting operations.

● Plasma cutting’s high-velocity jet delivers high energy, resulting in cleaner and faster cuts with minimal heat input.

● Fully integrated CNC plasma systems boost productivity, reduce errors, and enhance cutting precision.

● Adaptable plasma cutting for various industry needs, from automotive to artistic applications.

● Square edges and accurate tolerances are consistently achieved, enhancing the quality of the final product.

Precision plasma cutting has changed metalwork for the better. It lets us cut metal fast and accurately. A high-temperature plasma torch that is guided by advanced CNC systems melts materials quickly.

CNC plasma cutting shines by making detailed cuts on metals like steel and aluminum2. It uses automation for consistent, high-quality cuts. This is key in fields where precision matters a lot, like in making cars or planes. Advanced torches and cutting tech make better cuts, cut faster, and lower errors3.

CNC tech and plasma torches together make cutting super efficient. They speed up making things but use less material. The process starts with designing in CAD software, then moving to G-code2. This is great for complex designs that need to be very accurate. Plasma cutting is perfect for tricky profiles2.

In the end, CNC plasma cutting with top plasma tech shows great advancement in metalwork. These new methods mean better speed and quality for makers. By using these tools, they make better items faster.

In the world of manufacturing, staying on top is key. This means checking every detail and sticking to strict, high-quality plasma cutting standards. Our goal is to offer cutting-edge services that go beyond what our customers expect. Here, we talk about important practices that can make CNC plasma cutting even better.

Starting with the right material prep is a must. Making sure materials are clean and free from debris before cutting is vital. This is to avoid any mistakes and make sure that high-def plasma cutting gives you sharp, exact edges4. High-def CNC plasma cutting tables are the best choice. They can be used a lot more (over 3,000 starts) compared to cheaper ones (about 500 starts). This shows their value and long-lasting use.

Changing the cutting speed is crucial for the cut's quality and precision. High-def plasma cutting is much better for complex shapes than old methods like oxy-fuel cutting. This is important for complicated designs that need accurate solutions4. This feature ensures that materials are cut precisely without harming the overall structure.

For CNC plasma cutting to always work well, regular maintenance is key. High-def plasma cutters last longer and work better with routine checks. This makes them more reliable than cheaper models4. Regular maintenance helps avoid any unexpected problems. This ensures projects stay on schedule and meet high precision standards.

To wrap it up, good material handling, the right cutting speeds, and strong maintenance routines are crucial. These methods help improve how we produce things. They also make sure we meet the high precision and quality standards in metal processing and manufacturing.

Let's explore the power of CNC plasma cutting in the metalworking field. This tech mixes skill with speed. It's a key part of today's automated cutting systems. It owes its success to high-speed plasma jets. These jets make exact cuts through many electric materials.

CNC plasma cutters work by turning gas into plasma that's very hot, like the sun. This plasma can get hotter than 20,000°C5. It becomes a fast-moving jet that cuts materials quickly and accurately6. This feature boosts the cutting speed and allows for more work without sacrificing quality.

The temperature of the plasma, reaching up to 30,000°C, is key for clean cuts. It works well for both thin and thick metals6. By controlling the molten metal, it makes sure the cut is high quality and the metal stays strong.

Messer Cutting Systems offers CNC plasma setups customized for different needs. Systems like the MetalMaster Xcel and the Titan III enhance work efficiency5. Their versatility makes them useful in many industries, from cars to big industrial projects. This shows why CNC plasma cutting is the top method of precise manufacturing.

In short, CNC plasma cutting's mix of high-speed jets and temperature control is key for precision cutting. It helps businesses grow by improving their production. This makes them stand out in a tough market.

CNC plasma cutting is vital in many areas. It makes strong parts for cars and beautiful art from metal. This tech is key to new manufacturing methods.

In cars, CNC plasma cutting is essential for making complex parts. It cuts through thick steel fast. This helps production lines a lot.

This tech is also used in art. It lets artists make detailed works out of metal. Plasma cutting is flexible and boosts creativity in metal arts.

CNC plasma cutting is a big part of advanced manufacturing. It works with computers for accuracy and speed. This is vital in industries that need precise cuts.

Plasma cutters can cut different materials. These include steel and aluminum. This is good for construction and shipbuilding7. High-definition plasma systems give high-quality cuts7.

Different gases in the plasma process help make cuts better. They are used for thick materials or clean cuts. This keeps the design and material in good shape78.

CNC plasma systems use advanced software. This makes work flow better and automates tasks. It raises productivity and keeps quality high for big orders8.

The evolution of plasma cutting has been big. Now, with computer controls and software, it's a key part of precise manufacturing8. As it gets better, its role in making things efficiently will grow.

In the world of metalwork, we take great pride in our precision plasma cutting. This process uses CNC tech to get really hot. It can melt all kinds of metals with great accuracy9. These cutting systems have gotten really good since the 1950s. Now, they're even better, with more control10.

Our cutting solutions are very advanced, thanks to plasma. They are super precise, down to 0.001 inches. This shows our dedication to quality11. The right gases help us cut different materials perfectly. This keeps our work very accurate without losing quality10.

Accuracy, repeatability, and efficiency are key for us. They help us stay ahead in CNC machining. Our craft shows in every piece we make. Our commitment puts Mekalite at the top of metalwork. We meet all the tough demands with every cut.

CNC plasma cutting has many benefits. It makes precise cuts quickly and can work with many materials. It uses little heat, so materials don't get warped. Automated features also allow for detailed designs and high-quality output.

Using CNC machines with plasma torches leads to precise and clean cuts. This setup achieves complex patterns easily. It also ensures cuts are consistent, keeping both accuracy and speed high.

For the best cuts, start with clean material. Adjust the cut speed for efficiency and accuracy. Keep equipment well-maintained, and use top-quality consumables to ensure the torch works well for a long time.

High-velocity plasma jets are made by turning gas into plasma with an electrical arc. This plasma gets very hot, up to 30,000°C. It cuts conductive metals fast, which is great for many jobs.

Precision plasma cutting is used in many fields. In automotive, it makes detailed parts. Artists use it for decorative items. And it's key in shipbuilding and construction for precise assembly.

CNC plasma cutting showcases the Craftsman archetype through innovation and quality. It emphasizes precision, reliability, and detail. These are essential for professional-grade products.

Schreibe einen Kommentar