-

Call Now ! +86-13912367818

Call Now ! +86-13912367818 -

Email Now info@wxhlhg.com

Email Now info@wxhlhg.com

Explore how CNC technology enhances shipbuilding technology, boosting precision in maritime construction and design.

In the fascinating world of shipbuilding, Grandweld leads by using CNC technology. It started a new era in ship making that guarantees detailed engineering and better naval design1. Grandweld uses three advanced CNC cutting machines to mix skill with modern machinery. This boosts efficiency at the shipyard1. This detailed way of engineering allows for making exact parts. CNC technology ensures accuracy from the design stage to the final ship2.

Strategic Nesting software shines by organizing drawings on materials well. It cuts down waste and uses materials better. This shows how CNC technology helps make shipbuilding more sustainable1. This blend of top CNC machines and skilled operators leads to a system focused on precision. Each part is made with care and tracked by part numbers. This keeps quality consistent through all shipbuilding stages12.

● Grandweld's precise marine engineering is elevated through the use of advanced CNC cutting machines.

● CNC technology plays a pivotal role in efficient and sustainable material usage in shipbuilding.

● Unparalleled accuracy in component creation is guaranteed via CNC technology.

● Integrated tracking systems in CNC machining support thorough quality management.

● Expert CNC machine operation underscores safety and effectiveness within shipbuilding.

Grandweld's top-notch gear and CNC experts bring a new level of shipbuilding. It ensures every part of the ship meets high standards of precision and strength12. Using CNC technology is not only about meeting high standards. It's also about leading the future of shipbuilding with a strong focus on quality and precision.

Today, CNC machining is changing the marine industry by improving precision. This is seen in ship design and making. Our skills in using CAD software help us make accurate parts for today's ships.

We use CAD software to turn ideas into detailed 2D and 3D designs. This step makes sure each part of the ship meets high standards and works right. Using advanced CAD makes changing designs into real parts much easier.

Nesting software makes marine engineering better by saving materials. It cuts down waste by using each metal sheet fully. So, we save money and help the environment too.

NC code lets CAD designs be made by CNC machines. It gives machines the steps to make parts perfectly. This precision is key, especially for complicated parts that must be just right.

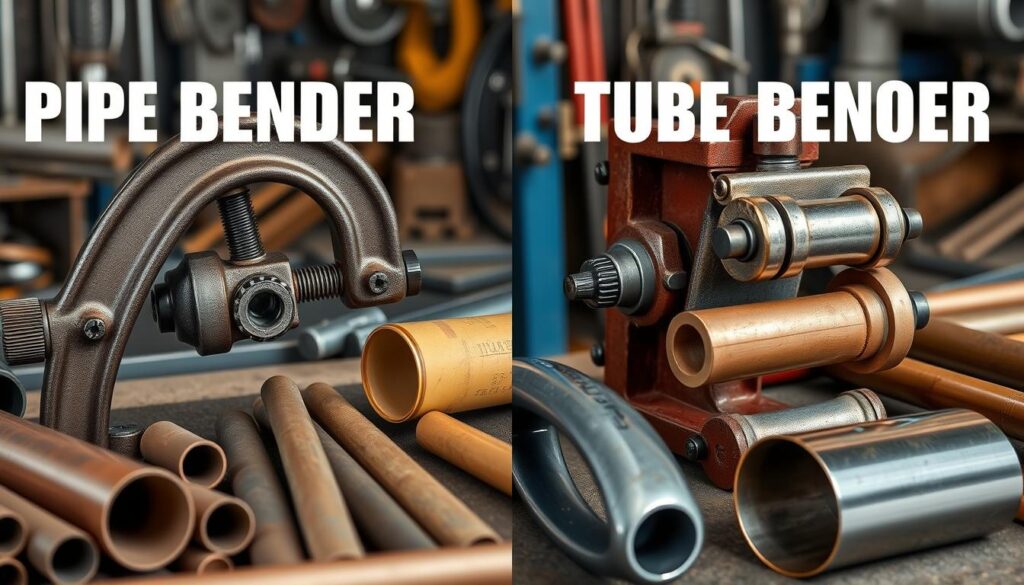

Shipyards are moving towards machines to meet the need for bigger, advanced ships. This increases how well they make things3. Using machines, like at Grandweld Shipyards, makes building ships better and faster3. This includes robots that weld and machines that bend pipes4.

Numbers show these machine methods work better than the old ways4. They make ships more accurately and dependably4. Bringing in these systems cuts costs and makes building faster. Plus, it keeps up safety and quality3.

In today's market, shipyard management needs both marine tech knowledge and advances in fabrication. With CNC plasma cutting technology, places like Great Lakes Shipyard are changing how they handle construction times and quality control.

Using automated cutting systems has really helped increase both precision and efficiency in shipyard management. For example, Great Lakes Shipyard added the Koike Aronson Plate Pro Extreme 3100 plasma cutting table. This has made cutting detailed shapes faster, greatly boosting how quickly work gets done5. These CNC plasma cutting machines are super fast and precise. This lets them easily create complex designs that keep ships strong6.

Good quality control is key to making shipbuilding better. The CNC plasma cutting tech at Great Lakes Shipyard lets them check parts thoroughly after cutting. This makes sure every piece meets tough standards. For example, the Plate Pro Extreme 3100 can make very smooth edges. This is very important for top-notch quality in thin parts5. Also, the system can mark part numbers on pieces. This makes putting things together easier and ensures the right parts are used5.

| Feature | Description | Impact on Shipyard Management |

| High-Temperature Cutting | Can reach over 20,000 degrees Celsius | Enables cutting through thicker and tougher materials efficiently6 |

| Versatility in Material Handling | Capable of cutting various materials including steel and stainless steel | Flexible fabrication options suitable for diverse ship components56 |

| Automation | Advanced automation features reduce manual labor | Increases productivity and consistency across projects6 |

| Safety Features | Includes enclosures and automated shutdown mechanisms | Ensures operator safety during intensive cutting operations6 |

The big changes caused by CNC plasma cutting technology in automated cutting and quality control are very important for shipyard management today. This tech helps make fabrication match design needs well and improves how shipyards work, giving them an edge in the busy world of marine technology.

The push for bigger, better ships has made shipbuilding technology leap forward. Using CNC in naval architecture makes building ships faster and more accurate to meet global needs7.

Modern shipyards turn to automation to solve worker shortages and improve safety by reducing manual work in risky tasks7. By using machines for welding, making parts, and painting, shipyards get better quality ships made faster7.

| Process | Impact on Efficiency | Quality Improvement |

| Automated Welding | Speeds up construction | Enhances accuracy7 |

| Automated Fabrication | Reduces downtime | Increases output consistency7 |

| Automated Painting | Standardizes application | Improves worker safety by reducing exposure to harmful substances7 |

Pairing CAD-CAM with CNC processes brings unmatched precision to design and building. This tech shows exactly where stress points, movement in water, and stability issues are, making ships safer8. CAD also helps meet tough IMO standards and supports teamwork, aligning every part of naval architecture perfectly8.

In wrapping up, adding CNC to shipbuilding technology isn't just trendy. It's a big step in improving naval architecture. This progress means our ships are built better, safer, and to the high standards our clients trust8.

Laser and plasma cutting have changed ship building. They make it precise, quick, and flexible. It's vital to know how these methods shape marine tech.

Laser cutting is known for its accuracy. It handles detailed work on thin materials fast910. It causes less damage from heat, keeping materials straight910. Plus, it can cut many types of materials, not just metals. This makes it a top choice in shipbuilding today9.

On the other hand, plasma cutting is great for thick metals. It cuts quicker in these cases9. However, it uses more power, which can cost more, mainly due to air compressors9. While not as precise as laser cutting, plasma cutting is cheaper at first.

Laser cutting may cost more at first, but it saves money later. It needs less upkeep and fewer parts. Unlike plasma cutting, its parts don't wear out quickly, saving money in the long run9. Using lasers well can also speed up making ships and cut costs, helping big shipyards10.

Laser and plasma cutting are pushing shipbuilding towards better, cheaper, and exact ways of making ships. These changes also help protect our planet.

Choosing between laser and plasma cutting depends on the job. Consider material thickness, needed precision, and your budget.

It's smart for shipbuilders to use both methods as needed. Use plasma's speed and price benefit for thick stuff. And laser's exactness for detailed work. This mix promotes innovation and keeps ship building moving forward with new tech.

Today's shipbuilding is better because of CNC technology. It makes building ships more precise and efficient. Every part of the ship fits perfectly together because of this. This makes the ship stronger and perform better.

CNC operations make design and assembly work together smoothly. The CNC router is very important in shipbuilding. It works fast and can handle many types of materials with great precision11. This helps make ships faster and stronger.

CNC machines are also key for making complex ship parts. They cut big sections of the ship accurately11. CNC nesting functions help use materials better and waste less11. This makes shipbuilding more efficient and saves time and money.

CNC tech is great for making ships the same way every time. It makes sure every measurement is accurate. This is very important for putting ship parts together right11. Keeping things consistent means the quality stays high across all ships.

Using CNC tech helps keep an eye on every step of building a ship. It makes sure everything is done right before moving on11. This focus on doing things right is very important for big projects. Even small mistakes can cause big problems.

| Feature | Benefits | Impact on Shipbuilding |

| CNC Precision Cuts | High Accuracy | Ensures structural integrity and alignment of components11 |

| Nesting Software | Material Optimization | Reduces waste, lowers costs11 |

| Digital Design Integration | Seamless transition from design to production | Improves production flow and efficiency11 |

So, CNC operations make shipbuilding better and stronger. They focus on doing things accurately and with high quality.

Modern shipbuilding faces tough challenges. Using innovative marine technology is key to overcoming these. Challenges like material hardness, making big parts with precision, and eco-friendly cutting are big. These technologies help ships work better, follow environmental laws, and improve quality in boat building.

Dealing with different material hardness and thickness is hard but necessary for ship safety and strength. New methods in oversize component precision help shape tough materials with less waste. Technologies like better laser and plasma cutting techniques keep the materials strong. This supports the need for sturdy ships.

Making big ship parts needs exact precision. Marine technology helps measure and cut these parts right. This precision speeds up building and lowers mistakes that could cost a lot later. Digital tech and automation have really helped manufacturers tackle these issues.

Being eco-friendly is very important in making ships. New eco-friendly cutting tech, like low-emission lasers, is changing how ships are built. These technologies lessen harm to the environment and meet global standards. The International Maritime Organization (IMO) wants to cut down greenhouse gases through these new solutions12.

The growth in marine technology innovations tackles challenges and helps build better ships. Using these technologies means managing resources better, making ships safer, and improving how they perform. This is good for both businesses and the planet.

| Challenges | Innovations | Impacts |

| Material Hardness | Laser Technology | Increased Durability and Safety |

| Oversize Components | Digital Fabrication | Enhanced Precision and Efficiency |

| Eco-friendly Measures | Recyclable Cutting Tools | Reduction in Environmental Impact |

In naval engineering, combining CNC operator expertise with detailed training is key. It ensures top-notch manufacturing results. Through marine engineering skills and naval engineering training, operators get good at the latest marine tech. They learn the best quality control practices too.

We focus on quality control in our training. Our courses cover marine propulsion to shipyard work. They teach practical skills and the safety and quality needed in shipbuilding today.

● Marine propulsion systems training enhances understanding of engines and efficiency13.

● Detailed marine electrical systems courses ensure adept handling of complex navigation and communication systems13.

● Our quality control workshops focus on inspection methods and assurance practices critical to shipbuilding13.

Our engineers gain hands-on experience in these trainings. This makes them ready to solve real problems with new ideas.

| Aspect | Impact on Shipbuilding |

| Quality Control Training | Increased precision in fabrication and reduced rework13 |

| Marine Engineering Training | Better designed, robust, and fatigue-resistant ships14 |

| CNC Operator Training | Enhanced ability to translate design into tangible outcomes14 |

It's important that our training meets industry rules. This ensures all work meets tough standards from authorities13. This way, we make our shipbuilding better and use resources well.

To sum up, by putting together naval engineering training and CNC tech, we greatly improve our CNC operator expertise. This led to better naval ships. It also builds a strong base for ongoing innovation and quality in the maritime field.

Looking back, adding CNC tech to shipbuilding has hugely changed the field. It shows the future of making ships. U.S. shipbuilders now get about $40 million extra each year from the ARPA MARITECH program thanks to CNC. This program improves how ships are designed15. Even though it's just a small part of their yearly sales, aiming to build 30 to 50 big ships every year matters. It is key to staying competitive globally15. Past government efforts like subsidies and Title XI have done more for the industry than tech programs have. They show that using many ways to grow and develop is important15.

U.S. shipyards are now making very advanced ships because of their high-tech skills. This level of innovation is at the heart of the field. But, getting better at this tech costs a lot. So, shipyards have to be smart about where they spend their money15. Reports from the Shipbuilders Council of America and MARAD show how crucial tech spending is. It really affects how well shipyards can compete. This is especially true in an industry where being innovative sets you apart from shipyards in other countries16.

The journey to being great at CNC machining is tough, for sure. Programs like NSRP are key for setting tech standards and evolution. However, shipbuilders need to invest more to really make a difference in the field15. As we move forward, we’re dedicated to keeping the Craftsman spirit alive. We’re always looking for new ways to improve how ships are built. Our commitment to excellence and sustainability drives us. It helps us lead the industry into a bright future where every ship is made perfectly and reliably.

CNC technology makes shipbuilding very precise. It does so by cutting, drilling, and milling exactly as planned. This is because of CAD files. They make sure everything is super accurate, important for designing ships.

CAD software helps engineers design ships digitally. This design is directly used in CNC machines. So, ships are built just as they were planned, making the whole building process better.

Nesting software saves materials in the shipmaking process. It arranges parts to cut from sheets smartly. This cuts down waste and is better for the environment, making resource use optimal.

NC code gives CNC machines their instructions for cutting ship parts. It's key for the parts to be consistent. This meets the strict needs of modern ship design.

CNC plasma cutting has made shipyards much more efficient. It speeds up cutting, making it accurate. This lets shipyards build better parts more quickly and dependably.

Quality control checks every part made by CNC machines against tough standards. This makes sure they all turn out as they should. This leads to ships that are well-made and reliable.

Using CNC in ship design makes building ships more efficient. It means cutting is accurate, and assembly is careful. CNC matches the detailed and precise needs of making ships.

Laser cutting is faster and more accurate than plasma cutting. It also makes cleaner cuts and is better for the environment. Its precision and waste reduction make it great for advanced ship making.

CNC solves many shipbuilding problems by being precise, fast, and reliable. It can handle tough materials and big projects. CNC also supports green cutting techniques, adding to its benefits.

Skilled operators make CNC technology do its best in making ship parts. They know the machines and materials well. This is needed for making high-quality, precise ships.

Leave a Reply